Rice boosts taste profiles for nonalcoholic beer, decreases fermentation time, and might add to taste stability.

Credit: Paden Johnson/CC BY-NC-SA

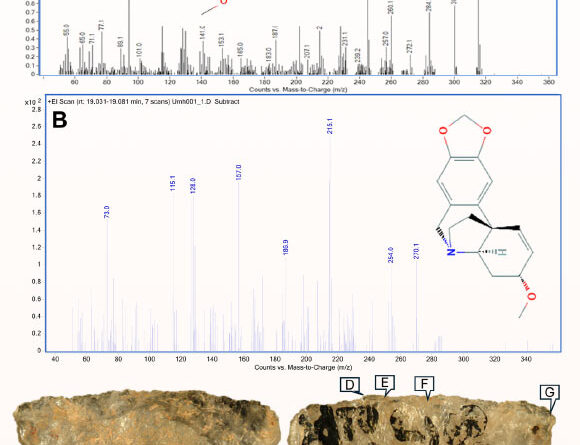

He and his group– consisting of Christian Schubert, a going to postdoc from the Research Institute for Raw Materials and Beverage Analysis in Berlin– brewed their own non-alcoholic beers, varying from those made with 100 percent barley malt to ones made with 100 percent rice. They performed an unpredictable chemical analysis to determine particular substances present in the beers and put together 2 sensory panels of cups (one in the United States, one in Europe) to evaluate fragrances, tastes, and mouthfeel.

The panelists identified the rice-brewed beers had less worty tastes, and the chemical analysis exposed why: lower levels of aldehyde substances. Rather, other sensory qualities emerged, most significantly vanilla or buttery notes. “If a brewer wanted a more neutral character, they could use nonaromatic rice,” the authors composed. In addition to developing beers with 50 percent barley/50 percent rice, this would produce non-alcoholic beers most likely to appeal more broadly to customers.

The panelists likewise kept in mind that greater rice material led to beers with a fatty/creamy mouthfeel– most likely due to the fact that greater rice material was associated with increased levels of bigger alcohol particles, which are understood to add to an enjoyable mouthfeel. It didn’t raise the alcohol material above the legal limit for a nonalcoholic beer.

There were cultural choices. The United States panelists didn’t mind worty tastes as much as the European cups did, which may describe why the previous selected beers brewed with 70 percent barley/30 percent rice as the optimum mix. Their European equivalents chose the opposite ratio (30 percent barley/70 percent rice). The description “may lie in the sensory expectations shaped by each region’s brewing traditions,” the authors composed. Fermentation likewise happened faster as the rice material increased since of greater levels of glucose and fructose.

The 2nd research study concentrated on screening 74 various rice cultivars to identify their extract yields, a crucial variable when it concerns an effective developing procedure, considering that greater yields imply makers can utilize less grain, thus cutting expenses. This exposed that cultivars with lower amylose material split more quickly to launch sugars throughout the mashing procedure, producing the greatest yields. And particular ranges likewise had lower gelatinization temperature levels for higher ease of processing.

International Journal of Food Science, 2025. DOI: 10.1080/ 10942912.2025.2520907 (About DOIs)

Journal of the American Society of Brewing Chemists, 2025. DOI: 10.1080/ 03610470.2025.2499768

Learn more

As an Amazon Associate I earn from qualifying purchases.