The brand-new proof-of-concept work, released in the journal Products Horizonsleads the way for self-assembling more complicated electronic gadgets without counting on existing computer system chip production strategies.

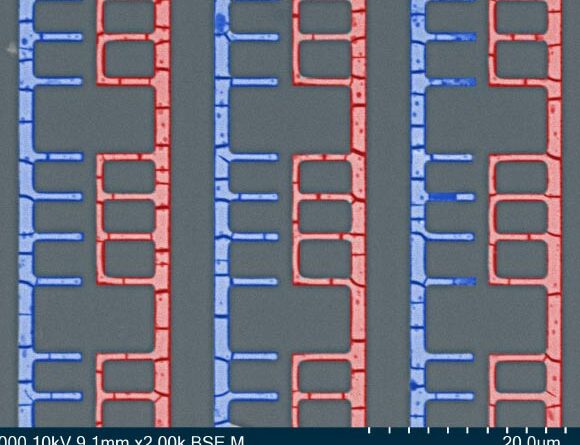

Bottom-up nano-to micro-fabrication is essential in modern-day electronic devices and optics. Traditional multi-scale variety fabrication methods, nevertheless, are dealing with difficulties in fixing up the contradiction in between the pursuit of much better gadget efficiency and reducing the fabrication expense and/or energy usage. Chang et alpresent a facile mixed-metal range fabrication approach based upon assisted self-assembly of polymerizing organometallic adducts originated from the passivating oxides of a ternary liquid metal to develop blended metal wires. Image credit: Julia Chang.

“Existing chip production strategies include numerous actions and count on exceptionally intricate innovations, making the procedure pricey and time consuming,” stated North Carolina State University’s Professor Martin Thuo.

“Our self-assembling method is considerably faster and more economical.”

“We’ve likewise shown that we can utilize the procedure to tune the bandgap for semiconductor products and to make the products responsive to light– indicating this method can be utilized to develop optoelectronic gadgets.”

“What’s more, present production methods have low yield, indicating they produce a fairly a great deal of malfunctioning chips that can’t be utilized.”

“Our method is high yield– indicating you get more constant production of ranges and less waste.”

“We call the brand-new, self-assembling method a directed metal-ligand (D-Met) response. Here’s how it works,” he included.

“You begin with liquid metal particles. For the proof-of-concept work, we utilized Field’s metal, which is an alloy of indium, bismuth and tin.”

“The liquid metal particles are put beside a mold, which can be made to any size or pattern. An option is then put onto the liquid metal.”

“The option includes particles called ligands that are comprised of carbon and oxygen.”

“These ligands harvest ions from the surface area of the liquid metal and hold those ions in a particular geometric pattern.”

“The service streams throughout the liquid metal particles and is drawn into the mold.”

As the option streams into the mold, the ion-bearing ligands start assembling themselves into more intricate 3D structures.

The liquid part of the option starts to vaporize, which serves to load the complicated structures better and more detailed together into a variety.

“Without the mold, these structures can form rather disorderly patterns,” Professor Thuo siad.

“But since the service is constrained by the mold, the structures form in foreseeable, balanced varieties.”

“Once a structure has actually reached the wanted size, the mold is eliminated, and the selection is warmed.”

“This heat separates the ligands, releasing the carbon and oxygen atoms.”

“The metal ions engage with the oxygen to form semiconductor metal oxides, while the carbon atoms form graphene sheets.”

“These components assemble themselves into a well-ordered structure including semiconductor metal oxide particles covered in graphene sheets.”

Teacher Thuo and coworkers utilized this method to produce nanoscale and microscale transistors and diodes.

“The graphene sheets can be utilized to tune the bandgap of the semiconductors, making the semiconductor basically responsive, depending upon the quality of the graphene,” stated Dr. Julia Chang, a postdoctoral scientist at North Carolina State University.

In addition, since the scientists utilized bismuth in the proof-of-concept work, they had the ability to make structures that are photo-responsive.

This enables the authors to control the homes of the semiconductors utilizing light.

“The nature of the D-Met method indicates you can make these products on a big scale– you’re just restricted by the size of the mold you utilize,” Professor Thuo stated.

“You can likewise manage the semiconductor structures by controling the kind of liquid utilized in the service, the measurements of the mold, and the rate of evaporation for the service.”

“In short, we’ve revealed that we can self-assemble extremely structured, extremely tunable electronic products for usage in practical electronic gadgets.”

“This work showed the development of transistors and diodes.”

“The next action is to utilize this strategy to make more intricate gadgets, such as 3D chips.”

_____

Julia J. Chang et alAssisted advertisement infinitum assembly of mixed-metal oxide varieties from a liquid metal. Products Horizonsreleased online November 25, 2024; doi: 10.1039/ D4MH01177E

This short article is a variation of a press-release offered by North Carolina State University.

Learn more

As an Amazon Associate I earn from qualifying purchases.