Hi, this is Ben Finio with Science Buddies,

and this video is an introduction to how to use a breadboard. This is a breadboard. It's a rectangular piece of plastic with a

grid of holes that allows you to easily and quickly build electronic circuits by pushing

electronic components into the holes. For example, simple circuits like this one

with a battery and an on/off switch to control a light. You can also build more complicated circuits,

for example lights that flash automatically, or robots of all different shapes and sizes. There are far more examples than we can list

in the beginning of this short video. At this point you might be thinking that this

doesn't really look like it has anything to do with bread. The name breadboard comes from the early days

of electronic circuits when people would literally use wooden boards with screws or nails driven

into them to make electronic connections.

Modern breadboards are made from plastic,

and come in all shapes, sizes, and even different colors. The most common sizes you will probably see

are full-size breadboards, half-size breadboards, and mini breadboards. Larger and smaller sizes are available, and

many breadboards come with tabs and notches on the side that allow you to snap two or

more of them together, but a single breadboard will be more than sufficient for most beginner

projects. Let's take a closer look at how a breadboard

actually works. The holes of a breadboard allow you to easily

push the leads, or metal legs, of a component like this LED into them, and then will lightly

hold them in place. This connection is strong enough that the

LED won't fall out on its own, but light enough that if you make a mistake, you can easily

pull it out and put it in a new location. Technically, these are called solderless breadboards

because they can make these connections without using solder, or melted metal, to permanently

bond electronic components together. Let's find out how breadboards can hold onto

components without using solder. If you flip a breadboard over, they come with

an adhesive backing that allows you to permanently stick them onto a project, for example, the

breadboard stuck to this robot.

If you remove that backing completely, like

I've done with this breadboard here, you expose a series of metal strips that are inside the

breadboard. These metal strips are what make mechanical

and electrical connections to the components you insert into the breadboard. We can remove one of these metal strips by

pushing it out from the front to see what it looks like up close. Each strip is a series of five clips that

line up with the holes in the breadboard. When you push a component into the breadboard,

these clips are what's actually grabbing onto the leads, like you can see here with this

LED. This breadboard is actually made from transparent

plastic, so you can see the clips from the outside. When you press a lead into one of the holes,

it's just getting grabbed onto by one of these clips. Let's take a closer look at the writing on

the front of your breadboard. Your breadboard has columns labeled from A

through J, and rows that start with one and go up to a number that depends on the size

of the breadboard.

These labels make it easy to follow directions

when building a circuit. For example, all of these holes are in column

C, and all of these holes are in row 12. Hole C12 is where column C intersects row

12. There are also long strips on either side

of your breadboard that are usually labeled with red and black or red and blue lines,

and also a plus or minus sign. These are called buses or rails, and are used

to deliver power to your entire circuit. Typically, the red one marked with a plus

sign will connect to the positive battery terminal, and the black or blue one marked

with a minus sign will connect to the negative battery terminal.

Some breadboards, like this mini one, do not

have power buses at all. Some full-size breadboards have power buses

that run the entire length of the breadboard, as indicated by the continuous, unbroken red

and black lines. Other ones have power buses that only run

half the length of the breadboard, as indicated by the break in the lines here. This is convenient if you have a circuit that

needs to be powered by two different voltage levels. In order to use a breadboard, it really helps

to understand how all the holes are connected. Let's take a look at hole A1 as an example. Remember that inside the breadboard are sets

of five metal clips. This means that hole A1 is electrically connected

to hole B1, hole C1, D1, and E1. It is not connected to hole A1 because that

hole is in a different row and they do not share the same set of metal clips.

It is also not connected to any of the holes

on the other side of the gap in the middle of the breadboard. That's holes F1, G1, H1, I1, and J1. We'll explain more about what this gap means

in a little bit. This diagram shows all of the connections

on the breadboard highlighted with yellow lines. Each set of five holes forming half a row,

that's those on the left in columns A through E, and those on the right in columns F through

J, is electrically connected. The power buses run vertically on the sides

of the breadboard, and are typically connected over more than five holes, although this can

vary from breadboard to breadboard. The individual power buses are not connected

to each other. Let's take a look at what all this means for

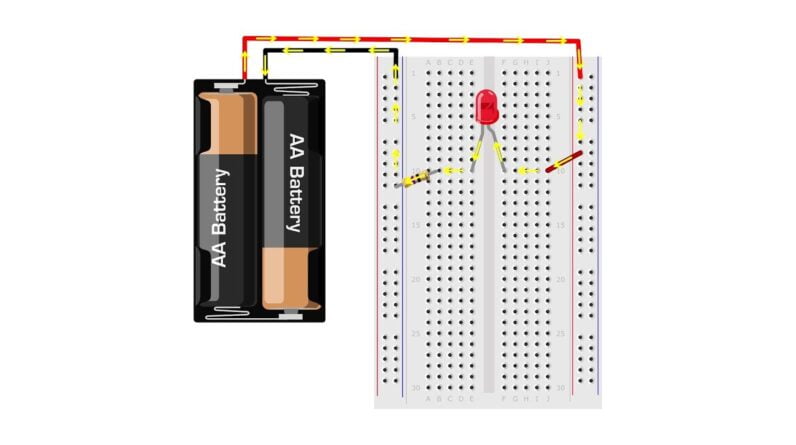

a common demonstration circuit with a battery, a resistor, and an LED. When I turn the battery pack on, the LED lights

up. Pretty simple. Now let's zoom in and see how I actually have

everything connected on the breadboard. The battery pack's red lead is connected to

the power bus on the right side of the breadboard.

This is connected to a jumper wire that goes

to row 5, which then goes to the LED, over to row 5 on the other side, to a resistor,

to the ground bus, and then to the battery pack's black lead. This diagram shows how electricity flows through

the circuit using yellow arrows. This is called a closed circuit, or a complete

path for electricity to flow. Remember that on each separate half of the

breadboard, the holes in row 5 are electrically connected to each other. This means, for example, that I can take the

leads of the LED and move them to different holes in row 5 and it will still light up. However, if I take the LED and move it to

a different row entirely, like row 4 or row 6, it does not light up because there is no

path for the electricity to flow.

It has to be in row 5 to have that complete

path. You can also reconfigure the entire circuit. For example, here I am going to move the LED

and the resistor over to the right side of the breadboard, and then connect the battery

pack's negative lead to the ground bus on this side. While this looks different, electrically it

is the same circuit, so the LED still lights up.

You can see that in this diagram by tracing

the yellow arrows, and noticing that there is still a closed path for the electricity

to flow through the LED. Now let's take a look at some of the most

common mistakes that students make when learning to use a breadboard. Here we have the demonstration circuit from

the previous part of the video, with a battery, a resistor, and an LED. At first glance, everything probably looks

fine, but when I turn the battery pack on, the LED doesn't light up. You won't know why unless you look closely

at the breadboard. When we zoom in, you can see that one of the

LED leads is actually in the wrong row. Notice how all of the connections are in row

5, except for this lead of the LED which is in row 4. Remember that rows 4 and 5 are not electrically

connected, so in order for electricity to have a complete path to flow, we have to move

that LED lead over to row 5, and then the LED will light up.

Every time you build a circuit, you should

always double check your wiring to make sure your connections are in the right place. Another common mistake is not firmly pushing

leads or wires into the breadboard all the way. Watch what happens if I pull this jumper wire

out slightly so the connection is loose. The LED will still light up intermittently,

but bumping the wire or shaking the breadboard can easily make the LED go out. To make sure the connections stay secure,

you have to make sure the jumper wire is pushed firmly into the breadboard on both ends. The same goes for other components like the

LED itself. You can see that if I pull the LED out slightly,

it might look like it's actually pushed into the breadboard, but it's actually very loose

and won't stay lit. This is because the leads aren't pushed in

all the way, so to make sure it stays on, you have to make sure the LED is pushed firmly

into the breadboard, along with the rest of the components.

The next common mistake will depend on the

individual components in the project you're doing. Some components have polarity, meaning the

direction they are facing matters. LEDs are a great and very common example. Notice how if I grab the LED and flip it around,

it doesn't stay lit. If you look closely at an LED, you'll see

that the two legs are actually slightly different lengths. The longer leg is the positive side, and has

to be connected to the battery pack's red lead. The shorter leg is the negative side, and

needs to be connected to the black lead. The resistor on the other hand does not have

a polarity associated with it, so I can flip the resistor around and the circuit will still

work just fine. When using a breadboard you'll have to decide

what type of jumper wires you want to use, and there are several different types available. First are these long, flexible wires that

come in many different colors and are usually sold in packs of at least 10. The wires themselves are very flexible but

they have metal pins attached to their ends that make them easy to press into the breadboard.

While these wires can be very convenient for

simple circuits, they can get very messy for complicated circuits, and as you add more

and more to a breadboard you'll eventually get a tangled nest of wires that can be very

hard to keep track of. Another option is to buy a jumper wire kit. This is a small plastic container that comes

with many different colors of wire that are pre-cut to certain lengths.

The ends of these wires are bent down 90 degrees

which makes them easy to press into the breadboard and keep the wire flat, which can make the

circuit much neater than the longer, loopier flexible wires. The downside of these kits is that they usually

only come with one or two lengths for each color, which can make it difficult to color

code your circuit. The final option is to purchase special spools

of wire called hookup wire, and use a tool called a wire stripper to cut them to length

and then strip off some of the insulation to make your own jumper wires. You can see here I'm just taking the spool

of wire, cutting a short segment of it, then using the wire strippers to strip insulation

off of each end. When you're done you just have to bend the

ends of the wire down, and then you'll be left with a piece similar to what comes with

the jumper wire kit, that easily fits into the breadboard. The advantage here is that you can buy several

spools of wire of different colors and then cut them to any length you want so you can

color code your circuit.

If you do decide to buy your own hookup wire,

you need to make sure you buy solid-core wire and not stranded wire. Solid-core wire has wire made of a single

solid piece of metal that is very stiff and easy to push into a breadboard. Stranded wire is made up of multiple individual

smaller strands, kind of like a rope. This makes the overall wire much more flexible,

but the ends are also flexible, and therefore much harder to push into a breadboard without

just bending them. If you were watching closely earlier in the

video, you might have noticed that I actually violated this rule when I connected the battery

pack, which comes with stranded wires. If you're in a pinch, you don't have access

to solid core wire or a soldering iron, you can take the end of a stranded wire and twist

the strands together as tightly as possible, and that will make it somewhat easier to push

into the breadboard, but it's still not the easiest way to go.

Finally, all this time you might have been

wondering what this gap that goes down the middle of the breadboard is for. This gap is designed such that integrated

circuits, sometimes just called chips, that come in a dual in-line package, meaning they

have two rows of pins, can fit nicely straddling the middle of the breadboard. When you have a new chip, you might need to

bend the pins together slightly so they'll fit into the breadboard, but then you just

have to line up all of the pins and press it in firmly, just like you would with any

other component.

This works great because now the pins on each

side of the chip are each connected to their own row. What you don't want to do is put the entire

chip just on one side of the breadboard so it's not straddling the gap. Remember that the pins in each row on either

side of the breadboard are electrically connected to each other, so if you put a chip in like

this, you are shorting out the two pins in each row.

Integrated circuits come in many different

sizes, and they all serve a special purpose, however all of them will fit directly into

a breadboard straddling this middle gap. You can find a written version of this tutorial,

along with other helpful electronics tutorials like how to use a multimeter and how to strip

wire all on our website, www.sciencebuddies.org. You can also browse our free library of over

1,000 science and engineering project ideas if you need a project to do for school, at

home, or just for fun.

As an Amazon Associate I earn from qualifying purchases.