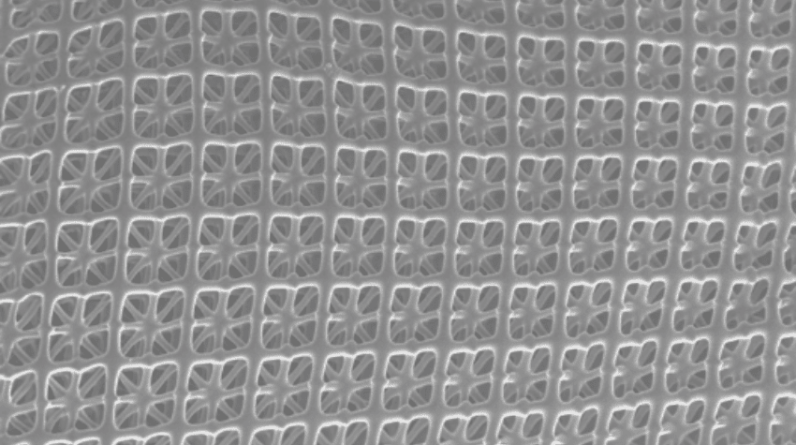

(Image credit: Peter Serles/University of Toronto Engineering)

Researchers have actually utilized expert system (AI) to create never-before-seen nanomaterials with the strength of carbon steel and the lightness of styrofoam.

The brand-new nanomaterials, used artificial intelligence and a 3D printer, more than doubled the strength of existing styles. The researchers behind the brand-new research study stated they might be utilized in more powerful, lighter and more fuel-efficient parts for planes and vehicles. They released their findings Jan. 23 in the journal Advanced Materials

“We hope that these new material designs will eventually lead to ultra-light weight components in aerospace applications, such as planes, helicopters and spacecraft that can reduce fuel demands during flight while maintaining safety and performance,” co-author Tobin Filletera teacher of engineering at the University of Toronto, stated in a declaration “This can ultimately help reduce the high carbon footprint of flying.”

In lots of products, strength and strength can frequently be at chances. Take a ceramic supper plate, for instance: while plates are typically strong and can bring heavy loads, their strength comes at the expense of strength– it does not take much energy to make them shatter.

Related: Researchers find innovative technique that makes fuel from water and sunshine– however it’s not completed yet

The very same issue uses to nano-architectured products, whose building and construction from wide varieties of small, duplicating foundation 1/100th the density of a human hair makes them strong and stiff for their weight, however can likewise trigger tension concentrations that result in abrupt damages. Far, this propensity to shatter has actually restricted the products’ applications.

“As I thought about this challenge, I realized that it is a perfect problem for machine learning to tackle,” first-author Peter Serlesan engineering scientist at Caltech, stated in the declaration.

Get the world’s most remarkable discoveries provided directly to your inbox.

To look for much better methods to create nanomaterials, the scientists simulated possible geometries for their style before passing them through a maker discovering algorithm. By gaining from the styles they had actually created, the algorithm had the ability to forecast the very best shapes that would equally disperse used tensions while likewise bring a heavy load.

With these shapes in hand, the scientists utilized a 3D printer to produce their brand-new nanolattices, discovering that they might hold up against a tension of 2.03 megapascals for each cubic meter per kg– a strength 5 times greater than titanium.

“This is the first time machine learning has been applied to optimize nano-architected materials, and we were shocked by the improvements,” Serles stated. “It didn’t just replicate successful geometries from the training data; it learned from what changes to the shapes worked and what didn’t, enabling it to predict entirely new lattice geometries.”

The scientists stated their next actions will fixate scaling up the products up until they can be utilized to make larger elements, while likewise looking for even much better styles utilizing their procedure. The main goal is to develop much lighter and more powerful parts for automobiles in the future.

“For example, if you were to replace components made of titanium on a plane with this material, you would be looking at fuel savings of 80 litres per year for every kilogram of material you replace,” Serles stated.

Ben Turner is a U.K. based personnel author at Live Science. He covers physics and astronomy, to name a few subjects like tech and environment modification. He finished from University College London with a degree in particle physics before training as a reporter. When he’s not composing, Ben takes pleasure in checking out literature, playing the guitar and awkward himself with chess.

The majority of Popular

Learn more

As an Amazon Associate I earn from qualifying purchases.