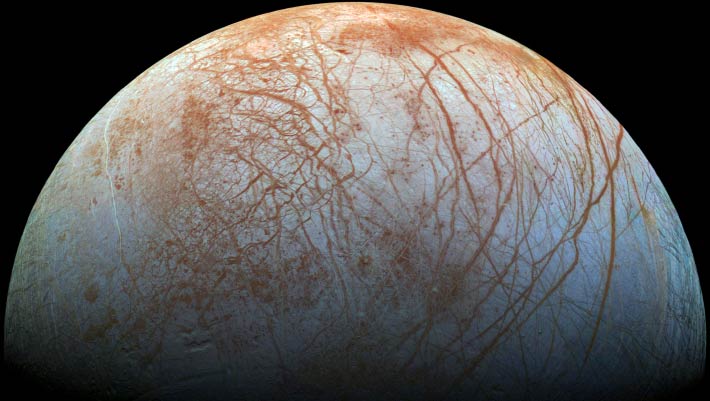

An E. coli nest imaged under an electron microscopic lense. The contagious germs might have an intense future in the fabric market, brand-new research study tips.

(Image credit: Getty Images)

Researchers have actually utilized genetically crafted germs to concurrently produce and color materials in a one-pot approach. Compared to present approaches that depend on nonrenewable fuel sources, the brand-new strategy provides an easier and more sustainable method to produce colored fabrics.

In a brand-new research study explained Nov. 12 in the journal Patterns in Biotechnologythe scientists produced cellulose-based materials covering the colors of the rainbow by changing the conditions utilized to grow the germs.

In current years, there has actually been a growing pattern to utilize an option approach of producing natural fibers from the fermentation of germs. Cellulose is an appealing target, as this product simulates the natural fibers discovered in materials such as cotton. A wide variety of germs generally transform glucose into fibers of cellulose to provide structural assistance and prevent other microorganisms. Cellulose produced by germs is naturally white, which indicates it frequently requires to be colored after processing.

Lee and his group have actually now streamlined this procedure by growing cellulose-producing germs together with microorganisms that produce natural colorants. The group utilized pressures of color-producing Escherichia coli (E. coli) to develop 2 classes of dyes: darker violaceins (which produced colors such as purple, blue and green) and warmer carotenoids (which produced colors such as red, orange and yellow).

The scientists genetically customized the metabolic path of a stress of Komagataeibacter xylinus germs to increase cellulose production throughout fermentation. Consequently including the violacein-producing E. coli to the response vessel led to purple-, blue- and green-dyed material.

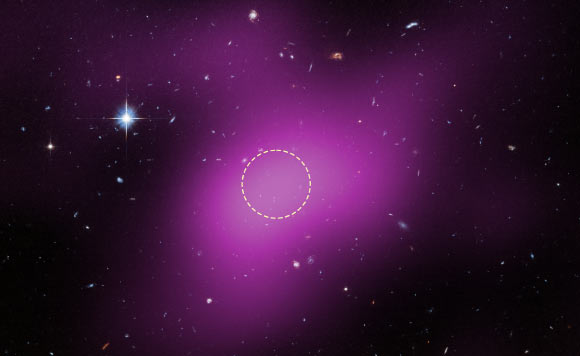

The complete spectrum of colored fabrics made by the E. coli germs utilizing the group

‘s brand-new technique.

(Image credit: Zhou et al., Trends in Biotechnology)The group was not able to utilize the exact same technique to attain the warmer tones, due to the fact that the germs did not produce adequate color to stain the cellulose material, likely due to bad bacterial development. To conquer this concern, they included pregrown and cured cellulose to a culture of carotenoid-producing E. coliThis co-culture technique effectively caused red-, orange- and yellow-dyed materials, thus finishing the group’s rainbow scheme.

Get the world’s most remarkable discoveries provided directly to your inbox.

In general, this approach “eliminates the need for separate dying and washing processes,” Lee stated, including that this assists to minimize chemical waste and water usage.

The colored bacterial cellulose revealed a total strong stability versus acids, bases, heat treatments, and cleaning. The group kept in mind that more work is required to totally check these products– significantly, to inspect their resilience versus commercial cleaning agents and mechanical wear and tear.

Progressing, Lee wishes to “extend the current seven color platform to a broader spectrum” and scale up the procedure to a commercial level while preserving constant quality. Additional modifying the method germs produce the cellulose might open other usages of the product, such as naturally degradable product packaging, he stated.

Mason Wakley is a freelance science reporter from the UK, many thinking about chemistry, products and ecological science. He was a 2025 Chemistry World intern. Mason has a masters in chemistry from the University of Oxford.

Learn more

As an Amazon Associate I earn from qualifying purchases.