NASA didn’t wish to state much about among the tests, and the other one lost its nozzle.

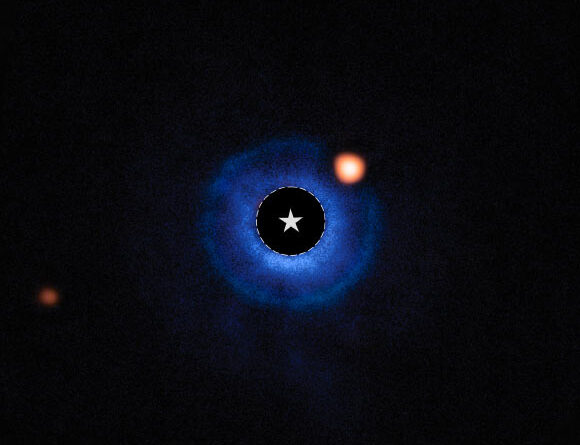

An uncontained plume of exhaust appeared near the nozzle of an SLS strong rocket booster minutes before its nozzle was damaged throughout a test-firing Thursday.

Credit: NASA

NASA’s Space Launch System appears to have a limited life span. The Trump administration wishes to cancel it after simply 3 launches, while the initial text of an expense making its method through Congress would extend it to 5 flights.

Opportunities are low the Space Launch System will make it to 9 flights, and if it does, it’s doubtful that it would reach that point before 2040. The SLS rocket is a core piece of NASA’s strategy to return United States astronauts to the Moon under the Artemis program, however the White House looks for to cancel the program in favor of more affordable industrial options.

For the 2nd time in less than a week, NASA test-fired brand-new propulsion hardware Thursday that the company would require to keep SLS alive. Last Friday, a brand-new liquid-fueled RS-25 engine fired up on a test stand at NASA’s Stennis Space Center in Mississippi. The hydrogen-fueled engine is the very first of its kind to be produced because completion of the Space Shuttle program. This specific RS-25 engine is designated to power the 5th flight of the SLS rocket, an objective called Artemis V.

On Thursday of this week, NASA and Northrop Grumman test-fired a brand-new strong rocket booster in Utah. This booster includes a brand-new style that NASA would utilize to power SLS rockets starting with the ninth objective, or Artemis IX. The motor evaluated on Thursday isn’t flight-worthy. It’s a test system that engineers will utilize to collect information on the rocket’s efficiency.

While the engine test in Mississippi obviously went according to strategy, the ground shooting of the brand-new strong rocket booster didn’t go rather as efficiently. Less than 2 minutes into the burn, the motor’s exhaust nozzle strongly shattered into numerous fragments of particles. You can enjoy the minute in the YouTube video listed below.

At the start of the program almost 15 years back, NASA and its backers in Congress pitched the SLS rocket as the powerhouse behind a brand-new period of deep area expedition. The Space Launch System, they stated, would have the benefit of recycling old area shuttle bus engines and boosters, fast-tracking the brand-new rocket’s course to the launch pad for less cash than the expense of a brand new lorry.

That didn’t turn out. Each Artemis objective costs $4.2 billion per flight, which’s with shuttle-era engines and boosters that NASA and its specialists currently have in their stocks. NASA’s 16 remaining shuttle bus primary engines suffice for the very first 4 SLS flights. NASA has remaining parts for 8 sets of strong rocket boosters.

It has actually been 10 years

Acknowledging that shuttle-era parts will ultimately go out, NASA signed an agreement with Aerojet Rocketdyne to set the phase for the production of brand-new RS-25 engines in 2015. NASA later on bought a preliminary batch of 6 RS-25 engines from Aerojet, then included 18 more to the order in 2020, at a rate of about $100 million per engine. NASA and its specialist objective to lower the expense to $70 million per engine, however even that figure is lot of times the expense of engines of equivalent size and power: Blue Origin’s BE-4 and SpaceX’s Raptor.

NASA test-fired a brand-new flight-rated RS-25 engine for the very first time last week at Stennis Space. The firm has actually typically supplied a livestream of its engine tests at Stennis, however it didn’t use the general public any live video. And this specific test was a quite huge offer. L3Harris, which got Aerojet Rocketdyne in 2023, has actually lastly reactivated the RS-25 assembly line after a years and billions of dollars of financing.

NASA made no public declaration about the RS-25 test till Monday, and the company didn’t discuss its task to fly on the Artemis V objective. If the Trump administration gets its method, the engine will never ever fly. Perhaps that’s great, however after so long with a lot taxpayer financial investment, this is a turning point worth advertising, if not commemorating.

L3Harris released a news release Tuesday validating the engine’s prepared usage on the 5th SLS objective. The engine finished a 500-second approval test, throttling approximately 111 percent of ranked thrust, showing more power than engines that flew on the area shuttle bus or on the very first SLS launch in 2022.

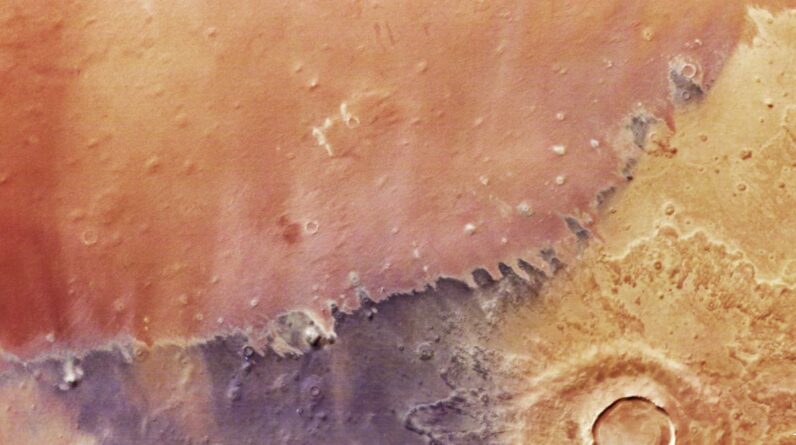

A brand-new RS-25 engine, No. 20001, was set up on its test stand in Mississippi previously this year.

Credit: NASA

“This successful acceptance test shows that we’ve been able to replicate the RS-25’s performance and reliability, while incorporating modern manufacturing techniques and upgraded components such as the main combustion chamber, nozzle, and pogo accumulator assembly,” said Kristin Houston, president of space propulsion and power systems at Aerojet Rocketdyne, L3Harris. “Our propulsion innovation is crucial to making sure the United States leads in lunar expedition, produces a continual existence on the Moon and does not deliver this tactical frontier to other countries.”

The test-firing last Friday came a couple of days before the 50th anniversary of the very first area shuttle bus primary engine test at Stennis on June 24, 1975. That engine brought the identification number 0001. The brand-new RS-25 engine is designated No. 20001.

Beware

NASA followed recently’s subtle engine test with the test-firing of a solid-fueled booster at Northrop Grumman’s rocket test website in Promontory, Utah, on Thursday. Kept in put on its side, the booster produced 3.9 million pounds of thrust, outplaying the power output of the existing boosters designated to the very first 8 SLS objectives.

Unlike the RS-25 shooting at Stennis, NASA picked to transmit the booster test. Whatever appeared to work out till 1 minute and 40 seconds into the burn, when an intense plume of super-hot exhaust appeared to burn through part of the booster’s structure simply above the nozzle. Minutes later on, the nozzle broke down.

Strong rocket boosters can’t be shut off after ignition, and for much better or even worse, the motor continued shooting up until it lacked propellant about 30 seconds later on. The rocket triggered a fire in the hills neglecting the test stand.

This was the very first test-firing of the Booster Obsolescence and Life Extension (BOLE) program, which intends to establish a higher-performance strong rocket booster for SLS objectives. NASA granted Northrop Grumman a $3.2 billion agreement in 2021 to produce boosters with existing shuttle bus parts for 5 SLS objectives (Artemis IV-VIII), and style, establish, and check a brand-new booster style for Artemis IX.

The boosters produce more than 75 percent of the thrust needed to move the SLS rocket off the launch pad with NASA’s crewed Orion spacecraft on top. 4 RS-25 engines power the core phase, jointly creating more than 2 million pounds of thrust.

Northrop Grumman calls the brand-new booster “the largest and most powerful segmented solid rocket motor ever built for human spaceflight.”

Among the most considerable modifications with the BOLE booster style is that it changes shuttle-era steel cases with carbon-fiber composite cases. Northrop states the brand-new cases are lighter and more powerful. It likewise changes the booster’s hydraulic thrust vector control guiding system with an electronic system. The propellant loaded inside the booster is likewise various, utilizing a mix that Northrop loads inside its business rocket motors rather of the dish utilized for the area shuttle bus.

Northrop Grumman has actually had a difficult time with rocket nozzles over the last few years. In 2019, a test motor for the business’s now-canceled Omega rocket lost its nozzle throughout a test-firing in Utah. Last year, a smaller sized Northrop-made booster flying on United Launch Alliance’s Vulcan rocket lost its nozzle in flight. Vulcan’s assistance system and primary engines fixed for the issue, and the rocket still accomplished its prepared orbit.

Stephen Clark is an area press reporter at Ars Technica, covering personal area business and the world’s area firms. Stephen blogs about the nexus of innovation, science, policy, and company on and off the world.

142 Comments

Find out more

As an Amazon Associate I earn from qualifying purchases.